Bump

good question Martin, i'd like to hear about that too!

| Official Luthiers Forum! http://www-.luthiersforum.com/forum/ |

|

| New to M and T neck joints http://www-.luthiersforum.com/forum/viewtopic.php?f=10102&t=7327 |

Page 1 of 1 |

| Author: | Martin Turner [ Wed Jun 28, 2006 4:10 pm ] |

| Post subject: | |

Okay, Im on my first steel string with a dovetail neck joint. The neck tenon has been cut allowing or a 1.5 degree neck rake. When the neck is fitted this means upper fretboard will be clear of soundboard if that area of soundboard is flat or doesnt have enough arch to meet the upper fretboard. What are options for dealing with this? Thanks and cheers |

|

| Author: | Martin Turner [ Wed Jun 28, 2006 5:14 pm ] |

| Post subject: | |

Okay, might as well try and work it out myself while waiting for the experts to respond. My steel string has a top with a 25" arch. Bracing was glued in with top in a 25" radius dish with centre of dish at bridge. If I lay a straight edge along centre line of top at the front edge of the top theres about a 3 -4mm gap between straight edge and top. This is same clearance I calculate for end of fretboard (21st fret). The fretboard tounge should be in contact with the soundboard with minimal working of the top. I think it makes sense but comments are most welcome. Cheers |

|

| Author: | Serge Poirier [ Thu Jun 29, 2006 12:09 am ] |

| Post subject: | |

Bump good question Martin, i'd like to hear about that too!

|

|

| Author: | A Peebels [ Thu Jun 29, 2006 12:12 am ] |

| Post subject: | |

Yup. You got it. Whoever worked out the angles, and radius needs a big pat on the back. It's pretty much standard proceedure now. Al |

|

| Author: | Martin Turner [ Thu Jun 29, 2006 12:18 am ] |

| Post subject: | |

I notice that some people put in a wedge under the fretboard tounge to fill any gap between tounge and soundboard. One or two people have no rake on the neck and vary thickness of fretboard instead....makes for a weird looking fretboard for the player. The topic is discussed in detail on Campiano's website and makes interesting reading. |

|

| Author: | Michael Dale Payne [ Thu Jun 29, 2006 12:25 am ] |

| Post subject: | |

OK if the top is flat as in with-out a 25' or 30' radius (not 25" radius  ) then you are right, you will have a 1.5 deg wedge shape gap. That is if the top is true perpendicular to the sides along the plane of the necks centerline. ) then you are right, you will have a 1.5 deg wedge shape gap. That is if the top is true perpendicular to the sides along the plane of the necks centerline.

This can be filled by a 1.5 deg wedge to match the FB extension. but before you make it and glue it up check your FB to bridge relationship to insure that 1.5 is the angle you need to achieve the proper FB to bridge plane |

|

| Author: | Martin Turner [ Thu Jun 29, 2006 3:03 pm ] |

| Post subject: | |

Okay...I have another dovetail joint related problem. At present the adjusting screw for the truss rod is protruding from end surface of dovetail tenon. This would be ok for a straight mortise and tenon but with angled dovetail the neck gets slipped down into the mortise. This means the protruding truss rod adjuster will catch on same. Should I move truss rod back so adjuster is flush with end of tenon? |

|

| Author: | TonyKarol [ Fri Jun 30, 2006 1:17 am ] |

| Post subject: | |

Martin - did you do some math, or take a measure from a drawing to get the 1.5 degrees ???? How do you know that 1.5 is what you need, rather than say 1.2 ??? I cut the heel angle ont eh neck after measuring the side to top angle at the heel area with a sliding bevel gauge - I really dont care what the number is for the angle, I just know that the bevel guage gives me the true angle required to get the bottom of the fretboard flat on the top (I use a 28 ft radius). I flatten the top in the FB extension area before taking the measurement (it doesnt take much - at 28 ft, the top curves only about 5 thou across a 4 inch span). I can then sand the fretboard top so that a straight edge lies in the plane to meet the bridge at 5/16 height. Very little if any tapering of the fretboards thickness is required to get this. I have never sat down and worked out the math as to why this is, it just works. As for your truss rod issue - I take it you have only an access hole thru the neck block ?? I use a routed slot, so the truss can always drop into the top from above, as would be done with a dovetail (I use a bolt on butt joint) |

|

| Author: | Don Williams [ Fri Jun 30, 2006 1:52 am ] |

| Post subject: | |

Well said Tony... Unless you have a cnc putting all this together and machining the parts, you won't get an exact angle until you measure. Important to all of this is flattening the surface of the top so that the fretboard sits on a flat surface rather than an arched surface. Once you've flattened that area, you can measure and end up with a very good neck joint with no 14th fret hump. |

|

| Author: | Michael Dale Payne [ Fri Jun 30, 2006 2:33 am ] |

| Post subject: | |

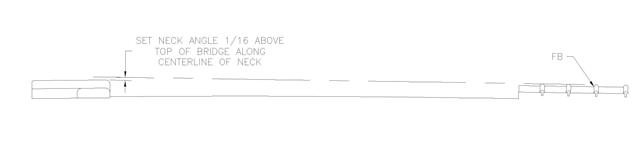

As Tony said even if your neck block only has a hole for the TR you can rout a channel access thru the top and neck block to allow the TR to drop in as you assemble the neck. If you are just noticing this, It tells me that you have not fitted the neck to the bridge yet or you would have noticed this during your fit-up. Again I will reiterate that the height of the plane formed by the FB centerline off the top of the bridge, with the bridge in its proper position, is critical for setting the required back angle. In fact this is the driving factor that sets the back angle. untill you have this data, any back angle you set is just a guess.  |

|

| Author: | Michael Dale Payne [ Fri Jun 30, 2006 4:02 am ] |

| Post subject: | |

I should have said as well that a 25' Radius lends it self well to this setup at 1.5 Deg (in generial) but the final angle is set based on the FB to bridge fit-up so the final back angle is very dependent on the bridge height at proper bridge location. |

|

| Author: | TonyKarol [ Fri Jun 30, 2006 5:10 am ] |

| Post subject: | |

One other thing to consider is how square the mold or jig is which holds the neck block as you glue the top or back on - any slight shift here (if you use a go bar deck, and do not use a block to block spreader, the neck block could tilt a touch from the go bar pressure on it)and then the angle changes again - thats why I measure after the body is together - it takes this into account if indeed something has moved. Put another way, the angle from the side to the top is really not important - you are concerned with the lie of the plane of the FB top - the lie has nothing to do with any side angle. Take a look at any guitar and imagine the heel angle (not the lie of the FB) is ten degrees steeper - so what, that just means the heel angle has changed - you are still aiming to get the FB to lie in exactly the same plane it is now. |

|

| Author: | Michael Dale Payne [ Fri Jun 30, 2006 5:29 am ] |

| Post subject: | |

I too do as Tony is saying. Enve though i know that my neck will fall somewhere very near 1.5 deg with my build setup. I do not take that into consideration at all till I fit up the neck. My bridge may be a 1/16" taller than what it would take to to fit 1.5 deg exact, I may have sanded my dome a bit forward shifted, As Tony said the neck block may have tilted the rim assembly a bit at glue up. 1/64" here will make a big differance in the neck set angle. Now in truth, my assembly method for my rims is such that I am very confident in the squareness of the blocks to the mold at glue up, but none the less I do not even begain to set the neck angle till I fit it with the fretboard attached to the guitar. Too little variance makes too big of an ajustment to assume 1.5 deg is right. |

|

| Author: | Martin Turner [ Fri Jun 30, 2006 12:37 pm ] |

| Post subject: | |

Thanks for all the replies chaps, I must admit planning is not the best for this instrument. Ive been building using spanish method untill now so alot of new territory being covered changing to building with seperate neck and body. To date Ive cut a slot in the soundboard to accomodate the truss rod. Im currently using a modified universal workboard ala Fox...Im just so used to an open building method and I already have a lot of money tied up in workboards and associated accessories. The 1.5 degree neck rake is what Ive used to date so I assumed it would suffice for future instruments. Points made here about actually measuring rake using body/top measurements make alot of sense. At this stage I have a neck made up and top is still at brace shaping stage and hasnt yet gone onto the workboard. I have the choice of carrying on with the neck, re doing the heel block (not alot of work) or starting again. On a steep learning curve with this construction tecnhique but still enjoying it despite a few disasters (getting good at taking off fretboards and pulling out truss rods). Cheers and thanks |

|

| Page 1 of 1 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|